A Complete Introduction To Faucet Parts

The different components that make up a faucet work together to ensure that the water flows smoothly and without any leaks。 we will be discussing all you need to know about faucet parts. We are a premier and professional Kitchen faucets manufacturer in China. In this article. We’ll dive into the various types of Faucet Parts’s introduction available, their functions, and how to replace them. We will also discuss some common problems that you may encounter with your faucet and how to troubleshoot them.

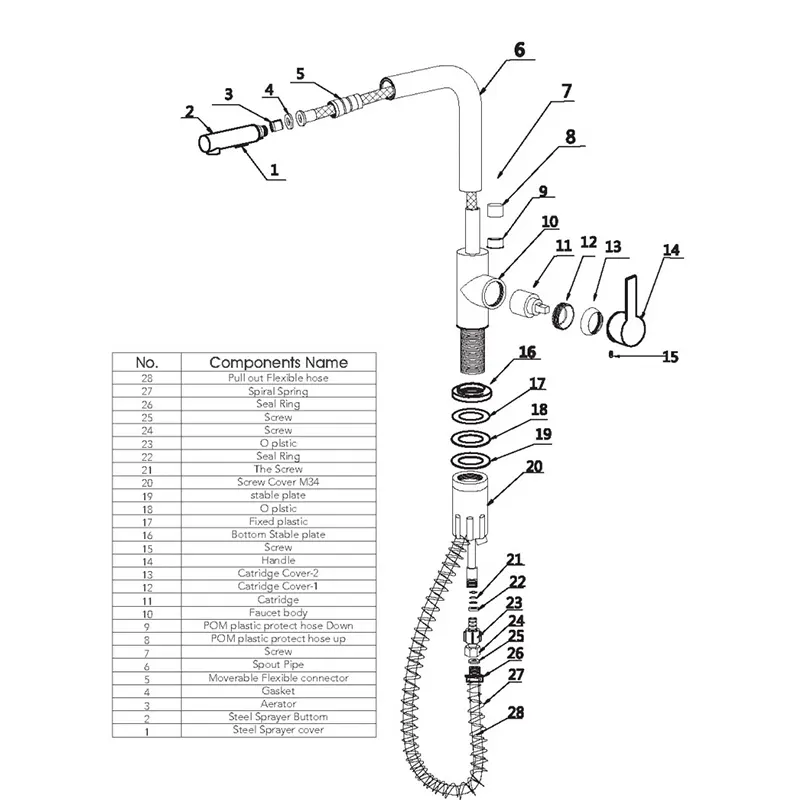

The Overall Faucet Parts Diagram

First, Please check the overall Faucet parts diagram, Then you will be clear all Faucet parts for kitchen faucets.

| No. | Components Name | Function/Purpose | Photos |

| 1 | Steel Sprayer cover | Covers the sprayer to protect it from damage and enhance the appearance of the faucet |  |

| 2 | Sprayer | Provides a high-pressure water flow for cleaning purposes |  |

| 3 | Aerator | Mixes air with water to create a steady, consistent stream |  |

| 4 | Gasket | Seals the connection between the faucet body and spout pipe |  |

| 5 | Movable Flexible Connector | Connects the spout pipe to the faucet body, allowing for flexibility and movement |  |

| 6 | Spout Pipe | Channels water from the faucet body to the spout and sprayer |  |

| 7 | Screw | Secures various components to the faucet body or spout pipe |  |

| 8 | POM plastic protect the hose up | Protects the hose from damage when it is pulled upwards |  |

| 9 | POM plastic protect the hose down | Protects the hose from damage when it is pulled downwards |  |

| 10 | Faucet body | Main component of the faucet, controls water flow and temperature |  |

| 11 | Cartridge | Regulates water flow and temperature within the faucet body |  |

| 12 | Cartridge Cover-1 | Covers the cartridge and holds it in place within the faucet body |  |

| 13 | Cartridge Cover-2 | Covers the cartridge and provides additional support |  |

| 14 | Handle | Controls water flow and temperature |  |

| 15 | Screw | Secures the handle to the cartridge cover |  |

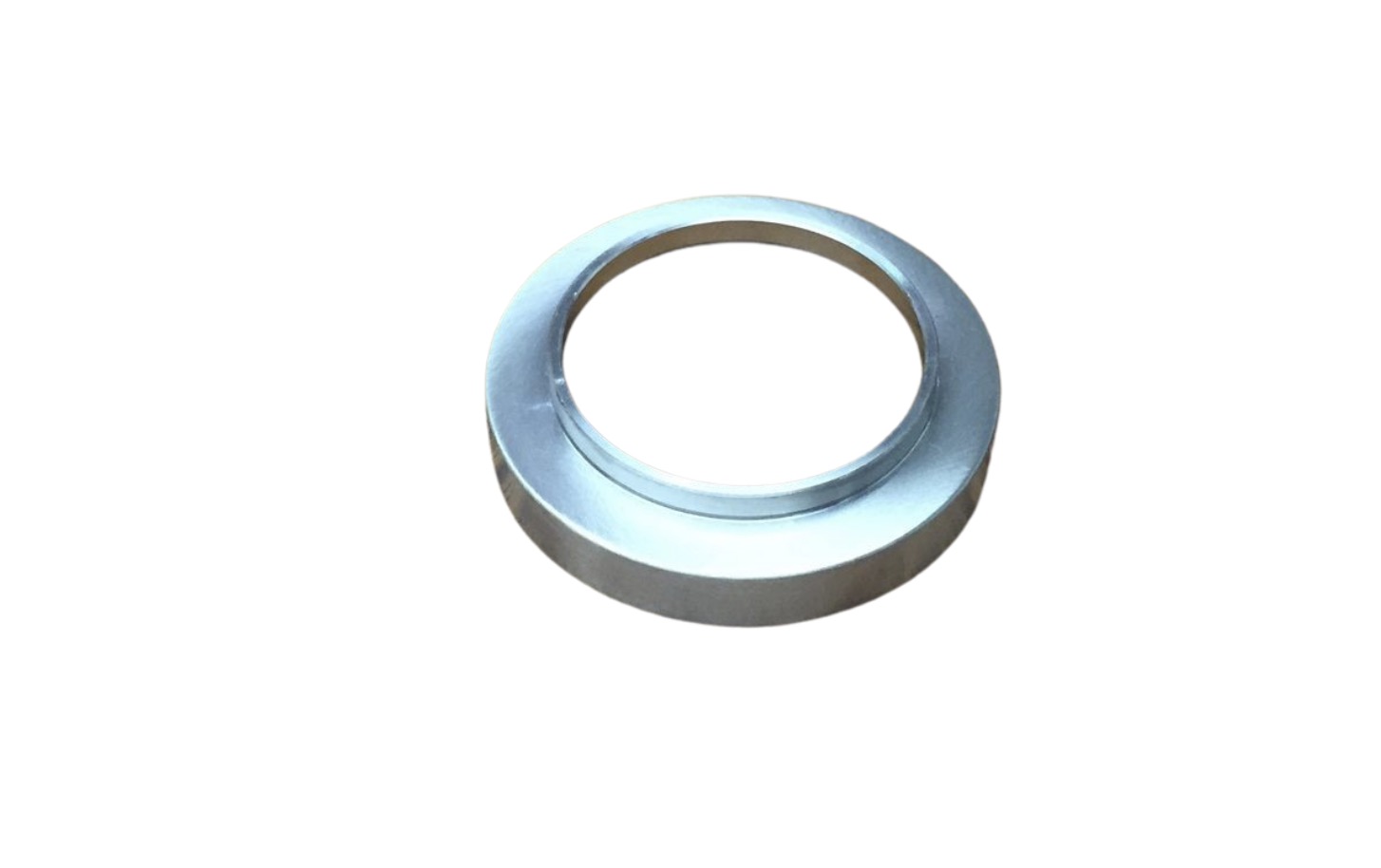

| 16 | Bottom Stable plate | Provides a stable base for the faucet on the countertop |  |

| 17 | Fixed plastic | Secures the faucet body to the bottom stable plate |  |

| 18 | O Ring | Seals the connection between the faucet body and stable plate |  |

| 19 | Stable plate | Supports the faucet and distributes weight evenly |  |

| 20 | Screw Cover M34 | Covers the screw and provides a finished look to the faucet |  |

| 21 | The Screw | Secures various components to the faucet body or stable plate |  |

| 22 | Seal Ring | Seals the connection between components within the faucet |  |

| 23 | O plastic | Provides a watertight seal for the faucet |  |

| 24 | Screw | Secures various components to the faucet body or spout pipe |  |

| 25 | Screw | Secures various components to the faucet body or spout pipe |  |

| 26 | Seal Ring | Seals the connection between components within the faucet |  |

| 27 | Pull out Weights | Provides flexibility and support to the pull-out flexible hose |  |

| 28 | Pull out Flexible hose | Allows for easy movement of the sprayer, and provides additional reach for cleaning purposes |  |

| 29 | Hot and Cold Water Inlet Hose | Supplies hot and cold water to the faucet. Made of flexible material such as rubber or PVC for ease of installation and durability. Connects to the water supply valves under the sink. |  |

It is divided into:

I, the water outlet component

Water outlet parts: 1, seal; 2, bubbles; 3, shower; 4, outlet elbow.

- Seal: The seal is usually made of rubber and is installed at the bottom of the water outlet to prevent water from leaking from the base. It is also called a gasket, and it is an essential component of the water outlet. Different faucets require different sizes and shapes of seals.

- Aerator/Bubble: The aerator or bubble is a component that screws onto the end of the faucet spout. It mixes air into the water flow, creating a gentler stream and reducing water noise. The aerator also helps to reduce water consumption by limiting the flow rate while still maintaining the same water pressure.

- Showerhead: The showerhead is an adjustable head that can change the water flow shape and direction, suitable for different use scenarios. It can be adjusted to provide a soft, gentle flow or a more powerful stream for washing dishes, filling pots, or other tasks. The showerhead can also be removed and used as a hand-held sprayer.

- Outlet Elbow: The outlet elbow is the component that directs the water to the desired location, such as a sink or vegetable washing area. It is usually made of metal and can be rotated or swiveled to adjust the direction of the water flow. Some outlet elbows also have a built-in aerator or a filter to improve water quality.

II, the water inlet and fixings

Water Inlet and fixing parts: 1, fixing; 2, Bottom fixing; 3, Kitchen Mixer fixing; 4, base fixing; 5 inlet hot and cold hose.

Water inlet and fixing parts are essential components of a kitchen faucet that connect the faucet to the water supply and ensure a secure and watertight installation. Here are the main components:

- Fixing: The fixing is a metal or plastic component that secures the faucet to the sink or countertop. It is usually installed from below the sink and is tightened with a mounting nut or bracket.

- Bottom Fixing: The bottom fixing is a metal or plastic component that connects the faucet to the water supply under the sink. It is typically installed on the bottom of the valve body and has threaded connections for attaching hot and cold water supply lines.

- Kitchen Mixer Fixing: The kitchen mixer fixing is a type of bottom fixing that is used for faucets with a single handle for controlling both the water flow and temperature. It typically has a ceramic cartridge or disc that controls the water flow and temperature and is easy to operate and maintain.

- Base Fixing: The base fixing is a metal or plastic component that covers the mounting hole in the sink or countertop and provides a secure and stable base for the faucet. It is available in different shapes and sizes to match different types of sinks and countertops.

- Inlet Hot and Cold Hose: The inlet hot and cold hose is a pair of flexible hoses that connect the faucet to the hot and cold water supply lines. They are usually made of braided stainless steel or nylon and have threaded connections that attach to the bottom fixing. The hoses are designed to be easy to install and are resistant to kinking and twisting, ensuring a reliable water supply to the faucet.

III, the operating component

Operating parts: 1, handle; 2, spool; 3, compression cap; 4, compression cap cover; 5, locking screw.

- Handle: The handle is the main control component for turning on and off the water flow. It is usually made of metal or plastic and can be in different shapes and sizes. The handle is connected to the spool or valve core through a shaft or stem, and it rotates to open or close the water flow. Some handles have temperature indicators or markings to show the direction of the water flow.

- Spool: The spool is the component that controls the water flow and consists of a valve core and a seal ring. It is usually made of brass or ceramic and is installed inside the valve body. The spool moves up and down or rotates to regulate the water flow and temperature. Different types of spools are used for different types of faucets, such as single-handle or double-handle faucets.

- Compression Cap: The compression cap is a component that is used to secure the spool and seal ring inside the valve body. It is usually made of metal and has threads that match the threads inside the valve body. The compression cap is tightened with a wrench to create a watertight seal and prevent leaks.

- Compression Cap Cover: The compression cap cover is a decorative component that covers the compression cap and provides a finished look to the faucet. It is usually made of metal or plastic and is available in different styles and finishes. The compression cap cover can be easily removed for maintenance or repair of the spool and seal ring.

- Locking Screw: The locking screw is a component that is used to secure the handle to the spool or stem. It is usually made of metal and is installed on the side or top of the handle. The locking screw prevents the handle from coming loose or falling off and allows for easy removal of the handle for maintenance or repair.

IV, the valve body. The four main blocks are described in full

Body (valve body): 1, Cast body; 2, Hot forged body; 3, Solid Stainless steel body; 4, New technology body.

Valve Body: The valve body is the main structural component of the faucet and is responsible for controlling the water flow and temperature. There are four main types of valve bodies:

- Cast Body: A cast body is made by pouring molten metal into a mold to create the desired shape. Cast bodies are usually made of brass or zinc alloy and are durable and resistant to corrosion.

- Hot Forged Body: A hot forged body is made by heating a metal bar and then hammering it into the desired shape. Hot forging creates a dense and uniform metal structure that is strong and durable. Hot forged bodies are usually made of brass or stainless steel.

- Solid Stainless Steel Body: A solid stainless steel body is made of a single piece of stainless steel and is highly durable and resistant to corrosion. Solid stainless steel bodies are typically found in high-end or commercial-grade faucets.

- New Technology Body: The new technology body is a relatively recent development in faucet design and is made using advanced manufacturing techniques such as 3D printing or laser sintering. These bodies are highly precise and can be made in complex shapes and designs that would be difficult or impossible with traditional manufacturing methods. New technology bodies are usually made of metals such as stainless steel or titanium.